| This area shows the construction and testing of a medium to large class Tesla coil. In this section, the previous coils were dismantled and a new larger coil, with a secondary over 6 inches, was redesigned and constructed for maximum efficiency at a power if about 1,440 watts. The tesla coil project is aimed mainly at the scientific and Tesla coiler community. I intend to use my Tesla coil for lightning demonstrations and entertainment. Note - This page may take a while to load on some SLOWER connections! |

The Tesla coils so far on this page were of low power and experimental in nature. This section shows a larger and more efficient coil built from scratch and within stricter adherance to the electrical rules involved in Tesla coiling. The new coil is a 1.5 KVA coil running off a bank of two 12KV, 60 mA NST's and sports a 6-inch secondary made from scratch! The secondary form for this coil is made of layered acrylic fabric sheets stiffened with styrofoam to form a 6-inch diameter cylinder and laminated with many layers of polystyrene resin (fiberglass clear boat resin). Each end is sealed and capped with 1/4 inch plexiglass and the form is close-wound with about 900 turns of #22 magnet wire. The tank circuit for this coil is a modified RQ spark gap with 10 3" x 3/4" copper pipe electrodes and 10 doorknob capacitors in parallel (each is 2500 pF at 30KV) yeilding 0.025 uF. The entire tank circuit is wired with 1/4" copper tubing encased in clear neoprene and heavy metal strip for the caps. The primary is a 15 degree inverted cone of 1/4" copper tubing with 1/4" spacing (about 10 turns tapped at 8). The support for the coil is a wooden frame about 18 inches high on casters for easy movement. There are three safety gaps, two formed by bolts on the doorknob EMMC bank, and one on the "supply panel" where two RF chokes (each 100 turns #22 wire on 1" PVC form) and HV terminals are. The panel safety gap forms a spark gap between the earth (RF) ground post and the two HV supply inputs. The toroids are easily interchangeable atop the secondary and are the two 11" salad bowl halves, or oversized (6" by 18" diameter) toroid. The system is supplied by a separate power supply which supplies the two HV terminals as well as spark-gap quench motor power. This unit contains two 12 KV 60 mA NST's in parallel with 130 uF PFC capacitor in parallel with each NST input. There is key switch and main power switch with indicator light which feeds a 10A variac for the NST's. A voltmeter is fed by a diode and 12V transformer showing 0-15 (x1000) volts. When powered up via the main switch, a buzzer sounds (which also can be silenced by a switch) as a HV warning alarm. There is also a dual outlet, one for the variac output and the other for the quench motor, also controlled by a switch. There are four HV outputs in the back of this unit on PVC cap "bushings". Two are from one NST, the other two are from the other. A "bus strip" parallels the two NST's at these output terminals. The HV wires are #14 house wire encased in neoprene tubing, and connect the PSU with the Tesla coil unit. The PSU also is on wheels for easy moving as it weighs about 75 pounds. This makes this Tesla coil system a 1440 Watt (1.5 kVA) medium power Tesla coil capeable of generating 4 foot plus arcs under the right conditions! Most pictures of this project are of the completed coil and setup / spark pictures. The only down side is that the older Tesla coils, including the dual unit and original PSU, were dismantled for the parts to build this version.

Lessons learned - Toroids and top-loads are VERY important for Tesla coil spark types! Further modifications to this version include using the 4x24 secondary (these are easily changed) from the dismantled old coil, using a well quenched spark gap. Also modified the copper tube type connections to reduce any "sharp" turns and solder them where necessary. Spark gap quenching is also very important, and an additional fan was added to improve quench air flow over the spark gap electrodes. Also modified secondary connections so that they can be changed quickly and easily. Also, you can use PVC for your secondary as long as it is thin-walled, sanded, dried, sealed FIRST, then wound and sealed thoroughly with urethane varnish. A similar secondary using boat styrene resin was easier to make, but cracks too easily when heated. Also made a supply "bus" of copper tubing with both ends connected to the HV primary supply post so that taps on the primary can be made ANYWHERE around the coil rather than just near the HV post.

Primary Transformer

Output Voltage : 12,000 VAC Maximum Current : 120 mA PFC Capacitor : 260 uF Frequency : 60 HZ Computed Power : 1440 VAPrimary Information (Overall)

Inside Diameter : 8.0" Total Diameter : 17.2" Length Of Wire : 32.02' Average Radius : 6.30" Wire Diameter : 0.25" Wire Spacing : 0.25" Winding Type : 15 Degree Inverted cone Maximum Taps : 11Secondary Information (Overall)

Diameter : 6.5" Length : 24.0" Radius : 3.25" Circumference : 20.42" Length Of Wire : 1484.6' Wire Guage : 22 Turns Per Inch : 37.48 Aspect Ratio : 1:3.69 Computed Inductance : 29.86 mH Computed Medhurst K : 0.67 Computed Self-Capacitance : 11.04 pF Computed Resonant Frequency : 277.18 KHz

Actual Tank Capacitance : 0.025 uF Top Load Major Diameter : 22" Top Load Minor Diameter : 4" Computed Top Load capacitance : 26.17 pF Required Primary Tap : 10.6 Turns Computed Resonant Frequency : 148.17 KHz

|

Here is a picture of the control panel of the power supply for my latest big Tesla coil being "ramped" up by turning the variac slowly clockwise. In this picture, the voltmeter indicates "5" for about 5,000 volts out on the neon sign transformer. The spark gap begins firing at around 4-5 KV out (about 1/4 power on the variac). |

|

This is a picture of my latest and greatest Tesla coil being powered up to near full power for the first time. In this picture, a beautiful streamer makes its connection with a grounding rod about 3 feet from the coil. The way the coil behaved was pretty interesting. When ramped up to full power, a small "brush type" discharge appeared at the 4x24 toroid breakout point (nail). In the course of about 30 seconds, the "brush" evolved into branching, withering streamers up to 40 inches in length. Two things cause this "latency", which is very normal for this type of coil. One is that the quench fan on the spark gap has to get up to speed thus allowing the caps to charge more before the gap fires. Second, the Tesla coil, its topload (toroid), and the earth (RF ground) are all capacitors, and the high-frequency RF field also creates a tremendous amount of static electricity, which has to "build up". |

|

This is a picture of a lonely first streamer about 20 inches in length that came out of a break-out point on my large 4x22 inch toroid running on my coil at about 1/2 power. The breakout point is a 3 inch nail on the surface of the toroid. |

|

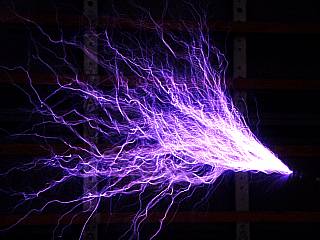

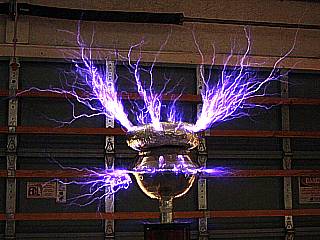

This longer exposure video frame grab shows the beautiful display of hot, multiple streamers coming off the break-out point when running my coil at near full power with two over-sized toroids (6x24 stacked atop a 4x24). These streamers are hot and very loud! Maximum spark-length here is about 36 inches. |

|

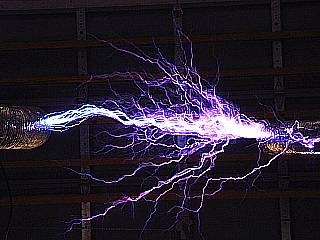

This is another exposure video frame grab showing the branching effect of the multiple streamers coming from the breakout point with two toroids on top my coil running near full-power. Note that there are two white-hot streamers, both going out of frame, one upwards and the other to a grounded cable near the floor. These streamers were approaching 40 inches in length. |

|

Here is a video grab showing my large Tesla coil running at full power with a 4x24 secondary (from my older coil I dismantled). It performed nearly as good as my 6x24 secondary! In this picture, a nasty, white-hot power arc takes a direct hit on the strike rail. Note I have two break-out points, one on each toroid. I removed the bottom one after this to reduce these strike-rail and even some primary power arcing (I counted at least 3 hits to the primary tap wire, and all fired my safety gap - but the coil just kept running)! The power arc in this picture is at least 24 inches long. |

|

This is a picture of the spark breakout from a nail on the 4x22 inch toroid of my Tesla coil running near full power. The streamers are over 30 inches in length. This picture is a 3-second exposure taken from a Fuji digital camera. |

|

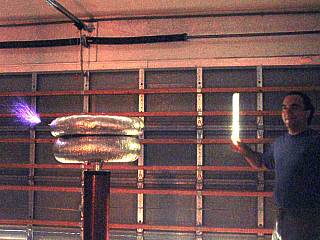

Here is another picture of myself holding one end of a fluorescent tube with my big Tesla coil running at 1/4 to 1/3 power in the background. This is a two-second time exposure taken with a Fuji digital camera. The coil is producing a small discharge (not visible to the left) and enough RF energy to light the tube between 5 and 10 feet from the coil. Another strange phenomina was that any ungrounded metal objects in the garage within 15 feet of the coil running even at low power produced a small arc to my fingers when touched. I was able to draw a small 1/4 to 1/2 inch arc from the metal handlebars of my bicycles to my finger tip giving me a tiny RF burn! Sort of scary effect of being in the "reactive RF near-field" of such a transmitter (Tesla coil). |

|

This picture shows my big Tesla coil running near full power with the smaller original top-load used on my earlier coils (a ball made with 2 steel 11-inch salad bowls topped with a 4x12 inch toroid). With nearly 1.5 KVA, the breakout length is slightly smaller with streamers less than 2 feet but much more frequent due to the smaller capacitance of the old top-load. |

|

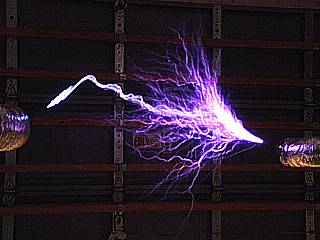

In this video frame-grab, I am holding a grounded discharge near the breakout points on my coil running near 3/4 full power. Again, white-hot power arcs, loud and terrifying, leap to the grounding rod. The power arc clearly is a brilliant blue and white channel of hot plasma. Note the "noise" in the video created from the intense RF field generated near the coil. My Canon 2000 EOS SLR camera simply kept "locking up" when I tried to take pictures this close, and only came back if I removed and replaced its batteries. Finally, my SLR took on a mind of its own and rewound the film (with a full unused roll in it) so I used the camcorder instead for these pictures! |

|

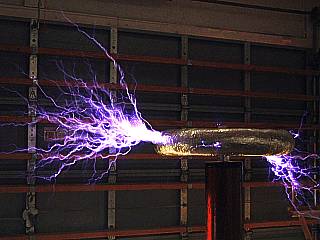

In this picture, with my big coil running at full-power, a power arc leaps from one breakout point (nail) on the coil toroid to a second nail on a grounded toroid at a distance of 36 inches (I measured it). |

|

This picture shows my big Tesla coil running at about 1/3 power and producing a discharge up to 10 inches from its breakout point. The RF energy generated lights the fluorescent tube in my hand as I stand at least 5 feet from the coil. |

|

This is a picture of a power arc slightly more than 3-feet in length (my personal record so far) from the toroid of my Tesla coil at full power to a grounded toroid spaced slightly more than 36 inches (measured with a tape measure). Exposure is 3-seconds with a Fuji digital camera and also captures countless streamers at nearly the same length. |

|

This picture is a 3-second exposure taken with a Fuji digital camera of my big Tesla coil running at full power. With the main breakout point (nail) removed, spark breakout was more random and energetic. The breakout seemed to favor the left and right sides of the 4x22 toroid in this picture. Note the one streamer extending below and to the left of the strike rail on the lower-left side of the picture. |

|

In this picture, streamers approaching 3 feet in length eminate from a rough area of aluminum on my 4x22 inch top-load torus when running my big Tesla coil at near full power. Note that streamers are also in the background as this shot is a 3-second exposure on a Fuji digital camera. |

HTML File "tcpart6.htm" - Developed By Chris Collura

To Return To The HOME Page Of This Site Click The "INDEX.HTM" Link Here!